The rise of additive manufacturing (also known as 3D printing) promises to revolutionize how companies build products. Ford Motor Company is revolutionizing the very production processes it popularized by adopting 3D printing and a renewed vision of cost savings and product innovation.

3D Printing has the potential to overhaul Ford’s product development processes by cutting costs and making higher quality products. Prototyping is traditionally a costly process for auto manufacturers. During prototyping, various parts are designed, created and tested in search of a final design that will be produced at scale cheaply. For each prototype, manufacturers customize machinery and create injection molds, with a new configuration required for each prototype. [1] With 3D printing, Ford can lower the cost of prototyping because a single, standardized 3D printer can create various intricate prototype designs without the additional tooling and configuration required in the traditional prototyping process. [2]

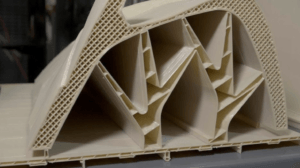

Ford plans to use 3D printing to improve product production at scale. With additive manufacturing, complex and innovative designs that are not possible with traditional, manufacturing processes become a reality. These parts are cheaper, lighter, and stronger than traditionally manufactured parts, making automobiles cheaper, more durable and more energy efficient. [3] These benefits lead to cost savings for consumers, serve to meet fuel efficiency regulations and create automobiles that are more durable for longer periods of time.

Clik here to view.

Ford is a 3D printing early adopter, having produced over 500,000 parts via 3D printing to date. Ford has reduced the time and cost of producing prototypes from 4-5 months and $500,000 to a “matter days a few thousand dollars.” [4] These prototypes are used across the entire automobile and are essential in drive and crash testing. [5] In the short-term, these cost savings are Ford’s most likely focus area given that 3D printing is still more costly at scale than traditional manufacturing.

Over the medium-term Ford and the automotive industry at large are expected to convert portions of their standard production process to 3D printing. According to Frost & Sullivan, by 2030, 3D printing in the automobile industry will be only 10% more costly than traditional manufacturing processes. [6] This rapid cost reduction will propel 3D printing to the mainstream because lightweight, strong automobile parts are a “cornerstone” of the industry. [7] Lighter, cheaper and stronger components that are only possible with 3D printing can decrease vehicle weight and improve fuel economy, giving Ford a competitive edge.

3D printing also promises to make customized automobile parts cost-effective. Similar to prototyping, customized parts require relatively higher amounts of tooling and configuration per part than large scale manufacturing because work is completed on one part at a time. However, customized instrument panels and limited-edition components are cost-effective with 3D printing. [8] Ford’s Stratasys Infinite Build 3D printer, located in its Research and Innovation Center is currently exploring personalized components for customers, something that has traditionally been limited to aftermarket job shops. [9]

As Ford looks to the future, it must carefully consider the implications of 3D printing on the automotive industry. Ford already cut its supplier network of 1,250 by 40% in 2013. [10] Cutting partners and replacing customized, manual work with automated, 3D printed work could cause major harm to the automotive industry and its workers. One way Ford can help manage this change is to help supply chain partners leverage 3D printing by proactively offloading certain additive manufacturing work to suppliers where it makes sense. Ford can also educate autoworkers in CAD and 3D printing, helping them gain relevant skills in a rapidly shifting market. [11]

Logistics providers are also concerned about the shift to 3D printing and companies like UPS have partnered with analytics and 3D printing companies to better understand how they must adapt their own infrastructure to the new realities of manufacturing supply chain. [12] In particular, lower quantities of shipped goods will reduce the number of shipments and the amount of goods stored in inventory, impacting logistics companies’ revenues. [13] Ford should bring its logistics partners closer and collaborate on reasonable, flexible logistics agreements so all parties can benefit from this new era of manufacturing.

While opportunities abound, there are still many unanswered questions about 3D printing and the automobile market. First, if consumers eventually get access to 3D printers capable of printing automobile parts, how will Ford prevent losing out on the profits from its intellectual property? [14] Second, will the opportunity for customized and “long-tail” replacement parts truly bear out and provide a stable revenue stream for auto manufacturers, or will these be viewed as gimmicks? As a global leader in both automotive and 3D printing, the world is looking to Ford to help answer these questions.

(777 words)

END NOTES

- W.J. Lim, K.Q. Le, Q. Lu, and C.H. Wong, “An overview of 3-d printing in manufacturing, aerospace, and automotive industries,”IEEE Potentials 35, no. 4 (2016): p. 19

- Craig A Giffi, Bharath Gangula, and Pandarinath Illinda. “3d opportunity in the automotive industry.” Deloitte University Press, May 19, 2014. p.8, https://www2.deloitte.com/insights/us/en/focus/3d-opportunity/additive-manufacturing-3d-opportunity-in-automotive.html, Accessed November 2018.

- Ibid, p. 9-10

- Ford Motor Company, “Building in the Automotive Sandbox,” https://corporate.ford.com/innovation/building-in-the-automotive-sandbox.html, Accessed November 2018

- Ibid

- Frost & Sullivan, “Global 3D Printing Materials Market in Automotive Transportation, Forecast to 2024,” February 7, 2018, p.10

- Ibid, p.11

- Five Ways 3D Printing Is Transforming the Automotive Industry, Stratasys corporate brochure, (Eden Prairie, MN, 2016), p. 5-6

- Ford Motor Company, “Ford Tests Large-Scale 3D Printing with Light-Weighting and Personalization in Mind,” https://media.ford.com/content/fordmedia/fna/us/en/news/ 2017/03/06/ford-tests-large-scale-3d-printing.html, Accessed November 2018

- Craig A Giffi, Bharath Gangula, and Pandarinath Illinda. “3d opportunity in the automotive industry.” Deloitte University Press, May 19, 2014. p.11, https://www2.deloitte.com/insights/us/en/focus/3d-opportunity/additive-manufacturing-3d-opportunity-in-automotive.html, Accessed November 2018.

- Ibid, p.17

- Brown, “Chain reaction: Why additive manufacturing is about to transform the supply chain,” Mechanical Engineering 140, no. 10 (October 2018), p. 35

- Ibid, p. 35

- Craig A Giffi, Bharath Gangula, and Pandarinath Illinda. “3d opportunity in the automotive industry.” Deloitte University Press, May 19, 2014. p.17, https://www2.deloitte.com/insights/us/en/focus/3d-opportunity/additive-manufacturing-3d-opportunity-in-automotive.html, Accessed November 2018.

The post Printing the Future: Ford Motor Company’s New Production Process appeared first on Technology and Operations Management.